Inductive heating is an important upgrade to the 6.0L FICM Strategy, especially for those with worn injectors or very cold climates.

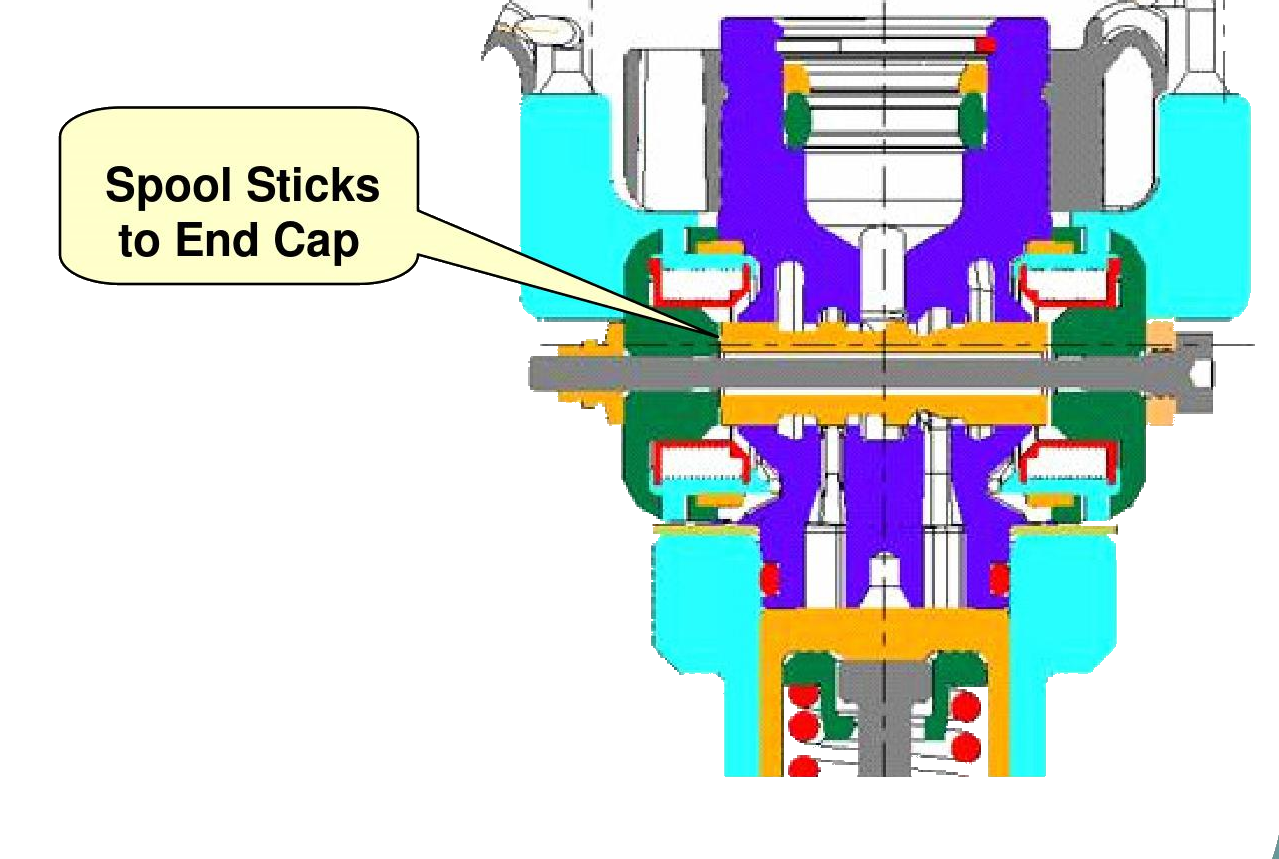

Inductive heating heats up the injector to pre-heat the oil and prevent "stiction", or sticking, of the

injector spool valve.

Stiction is caused by excess oil in the closed side end cap/spool interface area increasing the

hydraulic latching of the spool valve. Stiction increases as oil viscosity increases, Temperature

decreases, Oil viscosity changes, Oil ages , Oil additives, as well as Oil type and weight.

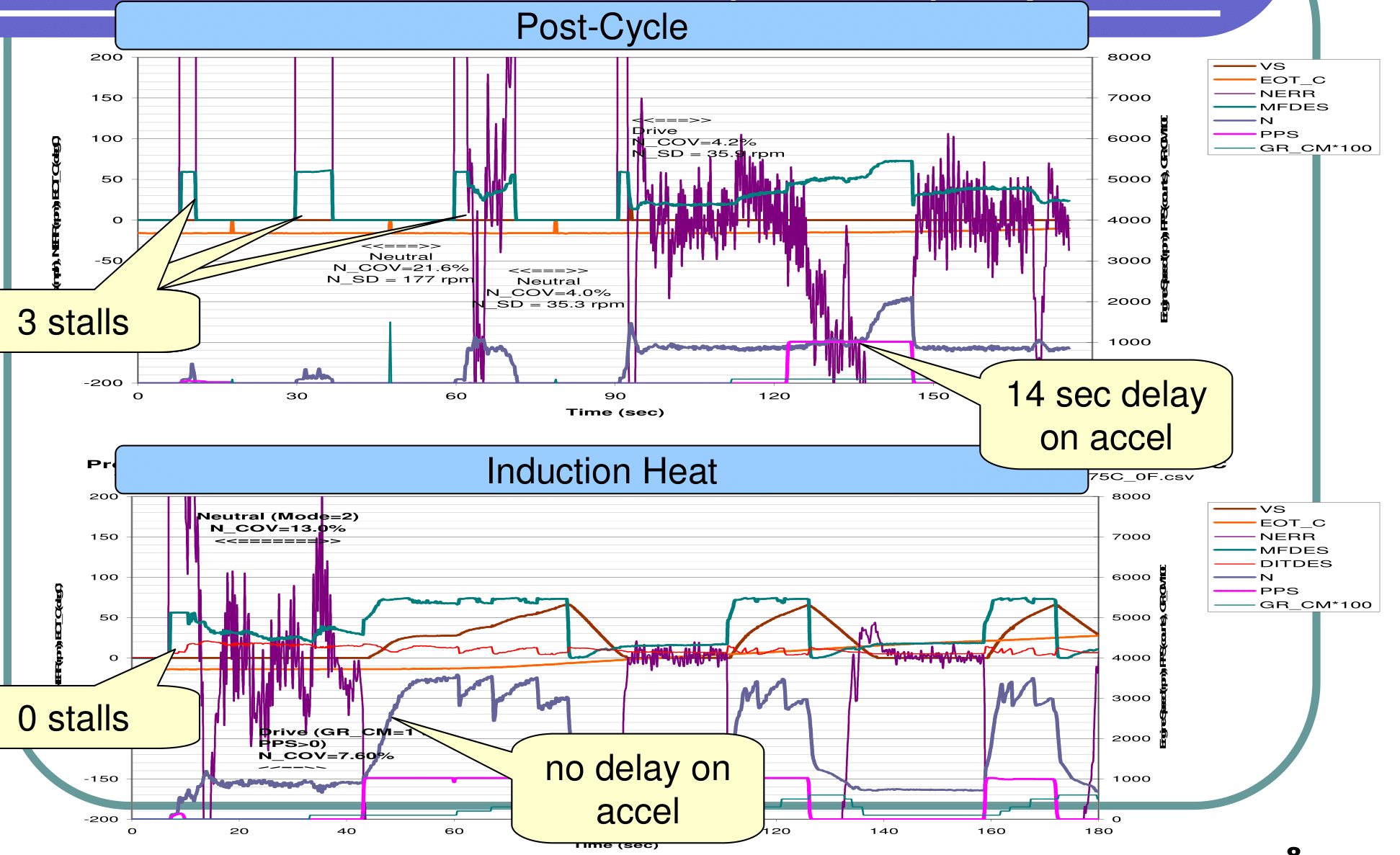

The colder and thicker the oil, the more delay causing:

-Rough idle

-Lacks power/no pedal response (extreme cases)

-White smoke

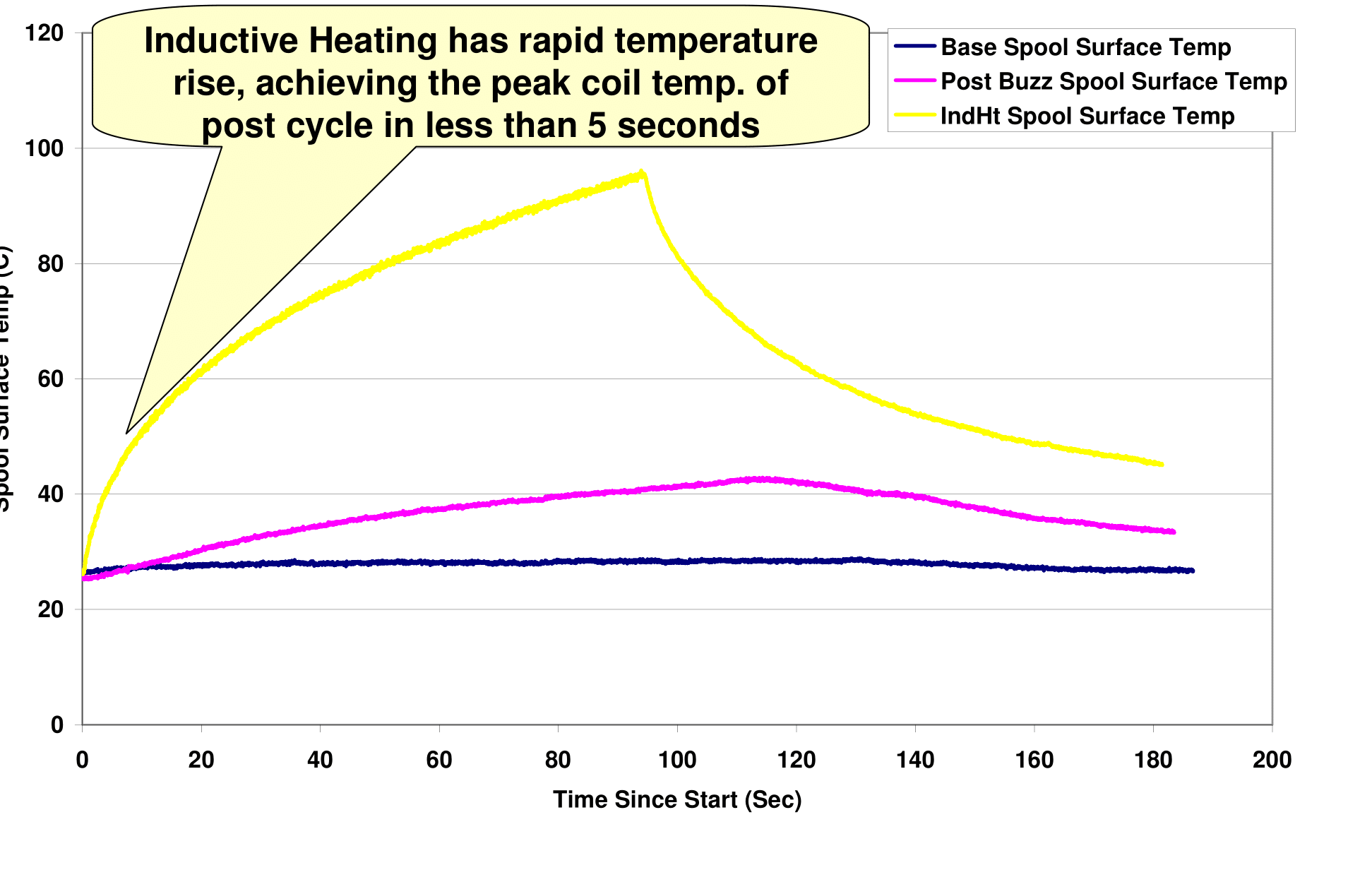

An Inductive Heat software solution has been developed and extensively tested in the lab and

field over the years. This is different from the post-cycle calibration release.

The new calibration applies current pulses to the injector coils in between injection events, which

inductively heats only the interface between spool and endcap. This causes the oil in that critical

interface to be heated MUCH more rapidly than by simply leaving the coils on longer, as with the

post-cycle calibration.

As with Post-Cycle, this heat makes the spool valve behave as it does when the EOT is hot. The

difference is that the heating method (Inductive vs. straight DC heat) is much faster.

This is a permanent fix, more effective long-term than injector replacement (since any injector can

develop stiction)

Ford 6.0L FICM Tuning for existing FICM's:

https://idspeedshop.com/id-ficm-tune/

Ford 6.0L FICM's with FICM tuning: