The Ford Powerstroke diesel engine has used an inferred exhaust back pressure (EBP) sensor strategy starting in the 2004 model year, with the 6.0L engine. The inferred EBP sensor strategy uses engine speed and boost pressure to calculate the EBP, rather than measuring it directly with a sensor. This method is less precise than a direct measure method, but it still helps to maintain the correct balance between exhaust gas recirculation and turbocharger output. The use of inferred EBP sensor strategy has been applied to the Ford 6.0L Powerstroke diesel engine, which was used in Ford trucks and other vehicles from 2004 to 2007.

The exhaust back pressure (EBP) sensor on the Ford 6.0L Powerstroke diesel engine is used to

measure the pressure in the exhaust system, and it helps to control the turbocharger's output. It's

often also referred to as the "Exhaust Back Pressure Tube".

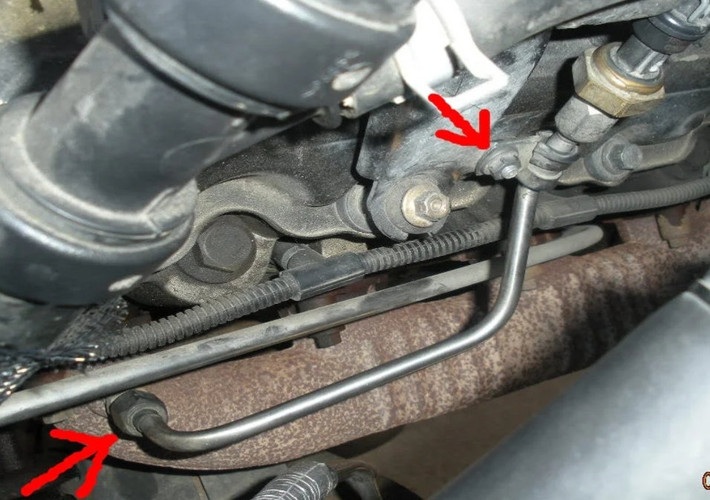

In the Ford 6.0L Powerstroke engine, the EBP sensor is located on the exhaust back pressure

tube, which connects the exhaust gas recirculation (EGR) valve to the turbocharger's outlet. The

sensor sends a signal to the engine control module, which uses the information to adjust the EGR

valve and the turbocharger's output. There were some common issues that happen with this

sensor, including : Dirty or clogged EBP sensor or tube, Wiring issue, Failed turbocharger VGT

solenoid valve. Symptoms that the sensor might be going bad include reduced engine power,

increased exhaust smoke, and poor fuel economy. In some cases, the check engine light may

also come on. Due to excessive issues with the EBP sensor and clogged tubes, Ford released a

recall for 2003-2004 trucks. This carried on for later trucks also. The reason for this recall is to

correct fuel injection timing during cold operation, EGR valve control, lack of power, check engine

light illumination (P02263 or P0299), hard starting and rough running concerns related to Exhaust

Back Pressure sensor corrosion. Other symptoms not listed in this recall, but which could occur,

would be excessive smoke, turbo control and surging at idle or cruise. The new update eliminates

the EBP sensor input to the computer. The exhaust backpressure will now be inferred/calculated

using other sensor signals.

The initial recall is as follows: Computer Programming Recall 06E17

2003-2004 F-Super Duty/Excursion 6.0L built before 9/29/2003 - exhaust pressure sensor input

no longer used if pcm is reprogrammed - service tip if the PCM on a 2003-2004 F-Super Duty or

Excursion 6.0L built before 9/29/03 is reprogrammed with wds release B41.8 and higher or B42.1

and higher, the new calibration contains a revised strategy that no longer uses the EBP sensor.

Exhaust pressure is now inferred, and even though the EBP sensor remains in place, it is not

used as an input and no longer can be viewed in data logger. These diagnostics include two new

dtc's, p006a (mass or volume air flow correlation) and p132b (turbocharger/ supercharger boost

control a performance), as well as the deletion of dtc's p0470 through p0478. also included in this

calibration are diagnostic improvements for p0231, p2287, and p0460.

Inferred EBP refers to a method of determining exhaust back pressure indirectly, rather than

measuring it directly with a sensor. An inferred EBP sensor uses other sensor inputs, such as

engine speed and boost pressure, to calculate the EBP. It's less precise than the direct measure

method, but it still helps to maintain the correct balance between exhaust gas recirculation and

turbocharger output. We've found, after the update and for 05+ 6.0L Powerstrokes, there is still

VRef supplied to the EBP sensor and the PID is not deactivated. Electrical shorts to the EBP

sensor within the harness or the sensor itself can still cause problems.