FORD 6.0 POWER STORKE (DTC)

P0117 ECT Engine coolant temperature circuit low input Signal short to ground, faulty sensor, faulty PCM

P0196 EOT Engine oil temperature sensor circuit range/performance Faulty circuitry, fault sensor, faulty thermostat, faulty PCM

P0232 Fuel Pump Fuel pump secondary circuit high Relay failure, short circuit, pump failure

P0381 GPL Glow plug/heater indicator circuit Open circuit, short to ground

P0528 FSS Fan speed sensor circuit no signal Mechanical failure, short to voltage, open circuit, short to ground

P0560 PCED System voltage Charging system failure

P0672 GPCM Cylinder 2 glow plug circuit Circuit open, short to ground, short to voltage, faulty glow plug

P0673 GPCM Cylinder 3 glow plug circuit Circuit open, short to ground, short to voltage, faulty glow plug

P0674 GPCM Cylinder 4 glow plug circuit Circuit open, short to ground, short to voltage, faulty glow plug

P0675 GPCM Cylinder 5 glow plug circuit Circuit open, short to ground, short to voltage, faulty glow plug

P0676 GPCM Cylinder 6 glow plug circuit Circuit open, short to ground, short to voltage, faulty glow plug

P0678 GPCM Cylinder 8 glow plug circuit Circuit open, short to ground, short to voltage, faulty glow plug

P0683 GPCM Glow plug control module to PCM communication circuit Open circuit, short to voltage, short to ground, faulty PCM

P1260 Theft detected, vehicle immobilized Anti-theft system failure

P1378 INJ Module FICM supply voltage circuit low Faulty connection, fuse, faulty relay, short to ground, charging system

P1531 PCED Invalid test — accelerator pedal movement Accelerator moved during KOER testing

P1705 TR Transmission range circuit not indicating park/neutral during self test Trans range failure

P1726 Insufficient engine speed decrease during self-test System voltage out of self-test range. Repeat the self-test.

P2122 APP Throttle/pedal position sensor/switch D circuit low input Faulty sensor, poor connection, open in signal circuit, signal circuit short to ground, faulty PCM

P2139 APP Throttle/pedal position sensor/switch D/F voltage correlation Difference in sensor readings

P2140 APP Throttle/pedal position sensor/switch E/F voltage correlation Difference in sensor readings

P2199 IAT Intake air temperature 1/2 correlation Difference between IAT and IAT2 exceeds a specified value

P2262 MAP Turbo/supercharger boost pressure not detected — mechanical Minimum boost under load. MAP hose disconnected.

P2284 ICP Injector control pressure sensor circuit range/performance A difference in commanded versus actual injection oil pressure was detected.

P2291 ICP Injector control pressure too low — engine cranking ICP cranking pressure too low

6.0L Power Stroke Diagnostic Information & Procedures

Note - see links at bottom of page for various related step-by-step 6.0L Power Stroke repair procedures.

| Key Terms/Acronyms | |

| OBD-II | On-board diagnostic system |

| MIL/CEL | Malfunction indicator light/check engine light |

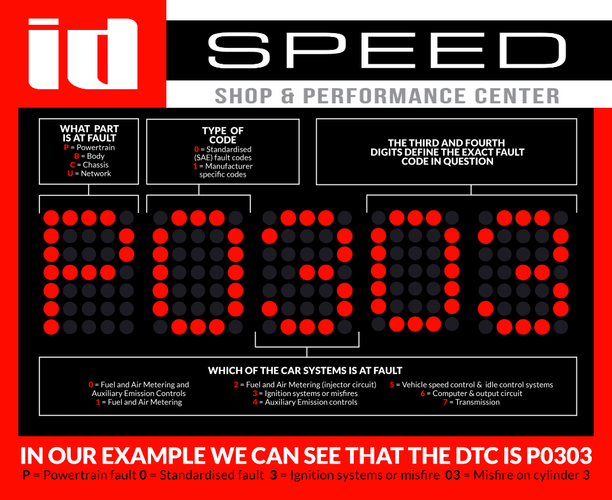

| DTC | Diagnostic trouble code (when a DTC is set, it may or may not trigger a CEL) |

| PID | Parameter ID |

| KOEO | Key on, engine off |

| KOER | Key on, engine running |

Smoke Signals - White, Black, & Blue Smoke Indications

The color of any visible smoke emitted from the tailpipe is a useful indicator in combustion characteristics (or lack thereof). Identifying smoke is particularly useful in hard start, no start, and performance related issues. A lack of smoke is equally beneficial in no start/hard start scenarios.

White smoke - White smoke is the result of raw, atomized fuel leaving the combustion chamber. Raw fuel is indicative that there is a lack of heat in the combustion chamber and therefore auto-ignition is not occurring. Recall that diesel fuel is ignited by the heat produced from compression. However, glow plugs serve as a starting aid to produce the heat necessary to begin the combustion process when an engine is cold. White smoke during cranking often points to a glow plug system issue; the engine is receiving fuel, but it is not igniting. White smoke while running may indicate a cylinder with low compression or, in certain circumstances, an injector that is stuck open. Note - "white" smoke may also be described as lightly gray in color.

Gray smoke - Gray smoke is the result of oil burning in the exhaust system. This is often caused by a turbocharger seal failure on the turbine (exhaust) side, causing engine oil to enter the exhaust system and burn. Under such circumstances, engine oil may drop from the tailpipe; this almost always indicates that a turbocharger replacement/overhaul is necessary.

Black smoke - Black smoke is the result of partially burnt fuel; there is adequate heat for combustion, however the mixture is rich and thus there is a lack of air or abundance of fuel during combustion. If black smoke is present and a low power condition is being experienced, an airflow issue is suspect (low turbocharger boost, intercooler boot leak, plugged air filter, etc).

Blue smoke - Blue smoke indicates that engine oil is being burned in the combustion chamber. The smoke resembles that emitted by a 2 stroke gasoline engine that is running rich. This typically indicates that there is a leak on the compressor side of the turbocharger via a failed seal.

Diagnostic Trouble Codes (DTCs) & Harness Chaffing

DTCs are your greatest asset and worse enemy when it comes to 6.0L Power Stroke diagnostics. In many situations, a DTC may indicate a system that is malfunctioning while the individual sensor that it refers to is not the problem. An injector control pressure low DTC, for example does not necessary mean that the ICP sensor is malfunctioning; although it might be. Another example is the occurrence of P2614 (camshaft position sensor) and P2617 (crankshaft position sensor) being set simultaneously. This is never an issue with the two sensors and almost always set as the result of a long crank, no start condition. The moral of the story is that a comprehensive diagnosis is always required until the underlying problem is identified and verified.

Harness chaffing is historically a serious concern on 6.0L Power Stroke engines. This is a common issue that surfaced shortly after the engine's release. Don't assume that this doesn't affect you - always perform a quick survey of your wiring harness and look for portions of wire loom that are chaffed or wires that are exposed. In extreme circumstances, wires can chaff inside the wire loom while the wire loom remains intact. If you're chasing electrical demons, this should be you're starting point.

A scantool or diagnostic software with enhanced diagnostic features is ideal when troubleshooting 6.0L Power Stroke engine problems. You need to be able to perform basic and advanced system tests in addition to monitoring the output of various sensors simultaneously. In the information below when we refer to "monitoring" a PID, we're doing so with AutoEnginuity's diagnostic software suite.

Notes about commonly misleading DTCs:

| DTC(s) | Notes |

| P1368 - FICM supply voltage low | Do not operate the engine until the root cause is found. This is typically triggered by a dead battery, which may also indicate that the alternator has failed. Bring the batteries to full charge, start the engine, and check the alternator with a multimeter/voltmeter. Low battery voltage can kill a FICM in mere seconds. |

| P2614, P2617 triggered simultaneously | P2614 and P2617 are camshaft position sensor (CPS) and crankshaft position sensor (CKP) DTCs, respectively. The odds that both sensors fail simultaneously is slim-to-none, especially considering failures of either sensor are not entirely common to 6.0L. Replacing the CPS is not particularly difficult, however reaching the CKP sensor will take you the better part of a day. These codes are generally triggered by a long crank condition. If you fall under this category, ignore and clear the codes. |

| P2284 - P2291, all injector control pressure (ICP) codes | ICP codes include out of range/performance, circuit low, circuit high, pressure low, pressure high, etc. Don't jump to the conclusion that the ICP sensor is faulty. Further diagnostics, including monitoring of the IPR valve duty cycle, are necessary to identify any DTC related to the high pressure oil system. |

| P2263 - turbocharger system performance | When turbocharger boost is low for a given condition, this DTC is set; it is generic and does very little to isolate the root problem. The most common issues with a 6.0L Power Stroke that would set this code are 1) VGT solenoid, 2) mechanically stuck VGT vanes in the turbine housing, 3) a blown intercooler boot (truck will have a low power condition), and 4) a failed MAP sensor. MAP sensor failures are not particularly common. Monitor MAP and VGT solenoid duty cycle while manually commanding the VGT vanes to open and close. If MAP does not change and/or there is no audible difference between the VGT open and closed, the vanes are mechanically stuck (extremely common) or the VGT solenoid is bad. If the vanes are changing position properly, continue to troubleshoot. |

| P0261 - P0280, all injector codes | An injector code does not always indicate that an injector is bad. The issue could be a chaffed harness, faulty FICM, or low injector control pressure. Monitor ICP, IPR valve duty cycle, and FICM function simultaneously while engine is idling. A cylinder contribution/power balance test will also isolate a cylinder with a dead injector. If it is suspected that an injector solenoid is sticking do to stiction, an oil additive such as Archoil 9R100 friction modifier may help free up the injector spool valve. |

| P0341 - cam position sensor | The engine will immediately stall if the CPS sensor loses signal as an injector cannot fire if it doesn't know where the cylinder is with regard to engine timing. If the engine did not stall but this code was set, do not immediately replace the CPS; it may not be the root cause. |

| P0401, P0402 - EGR flow insufficient, excessive | The EGR valve is likely mechanically stuck in either the open or closed position. EGR valves are expensive, cleaning them is not (a gasket kit is ~ $10). If code returns after cleaning, valve may have electrical issue and should be replaced. |

| P0471 - EBP sensor range/performance | An exhaust backpressure sensor DTC can be set for a number of reasons. In order to avoid replacing a perfectly functional EBP sensor, clean the EBP tube and see if the DTC returns. If it does, replace the sensor. The tube often becomes clogged with soot and this DTC is set once the sensor reading is found to be out of range for the ensuing conditions. Note - 2003 and early 2004 model year engines do NOT use the EBP sensor. It's there, but the PCM does not use the sensor. |

| P0603 - KAM | KAM is short for "keep alive memory", which is essentially information stored by the PCM through its various learning functions - transmission shift points, the VGT position schedule, and EGR schedule, for example. This code will be set anytime the batteries are disconnected for a period of time. The systems will all relearn perpetually and this should not be a concern. Transmission shift points and turbocharger performance may seem lackluster until these systems re-map themselves. |

6.0L Power Stroke No Start, HARD START, RUNS ROUGH, and/or Stalls

WARNING! - NEVER USE STARTING FLUID TO START A DIESEL ENGINE REGARDLESS OF PRODUCT CLAIMS. SEVERE ENGINE DAMAGE MAY OCCUR.

Check engine oil level - The 6.0L Power Stroke relies on a high pressure oil circuit to build fuel pressure. An engine will stall and a no start condition may occur if the engine oil level is low as it starves the high pressure system. No oil pressure = no injection pressure.

Verify battery condition - Low battery voltage can cause a slow crank condition and/or may contribute to FICM failure. Approximately 180 - 200 rpm cranking speed is required to start an engine. Battery voltage should measure 12.5 - 12.7 volts for a fully charged battery in good condition. If battery voltage is within this range but engine cranks slowly or intermittently, suspect corroded/loose connections and/or faulty starter.

Test for proper glow plug operation - A GPCM (glow plug control module) fault will typically set a DTC, a glow plug or glow plug wiring issue will not always set a DTC. Individual glow plug condition can be tested by measuring the resistance between each individual glow plug circuit at the GPCM and the negative battery cable. If white smoke is present while cranking, a glow plug system issue is likely (fuel is being injected into the cylinders accordingly but there is a lack of heat necessary for combustion to occur). If no smoke is present while cranking, the glow plug system is unlikely the cause of a no start/hard start condition.

Glow plug cycle time is determined by engine oil temperature (EOT) and barometric pressure. If the glow plugs do not cycle, verify the readings of these sensors (barometric pressure is equal to atmospheric pressure, EOT should read close to ambient temperature when engine is cold).

Verify ICP & IPR valve function - A minimum 500 psi injector control pressure is necessary to start the 6.0L Power Stroke diesel. If oil pressure does not reach or drops below 500 psi an injector will not fire. ICP typically reaches anywhere between 800 and 2,000 psi while cranking. If ICP sensor reading is low, erratic, rises slowly while cranking, or there is another reason to suspect it is bad unplug the sensor and attempt to start the engine (ICP defaults to 750 psi when sensor is unplugged). If engine starts, ICP sensor must be replaced.

The IPR duty cycle relates to the position of the IPR valve. At 15% duty cycle, the IPR valve is fully open. At 85% duty cycle, the IPR valve is fully closed. In the closed position oil pressure is increased and in the open position oil pressure is reduced (HPOP pressure bled off into the crankcase). Monitor ICP actual, ICP desired, and IPR valve duty cycle simultaneously. While cranking engine, IPR duty cycle should start at approximately 85% and slowly decrease during a long crank condition once ICP climbs. An IPR valve defaults to 15% if it is unplugged or has failed. In this instance, an engine will not start as it will not be able to build oil pressure; a low ICP condition should be present. IPR valve duty cycle should not exceed 30% at idle once the engine reaches operating temperature. If it does, suspect a leak in the high pressure oil circuit.

ICP actual will tend to trail ICP desired (what the PCM is commanding) while cranking, but the two should generally be close. If ICP desired is significantly higher than ICP actual the IPR valve may not be functioning correctly and is allowing oil pressure in the high pressure circuit to bleed off. A high pressure system leak (failed o-ring, for example) or bad high pressure oil pump (HPOP) can also cause a low ICP condition. Always verify IPR function before assuming high pressure oil system leak or HPOP failure. A high pressure oil system bleed down test is typically necessary to locate leaks. The test requires a special fitting that allows the system to be pressurized with air while the IPR valve is remotely commanded closed; leaks are then audibly traced.

Verify FICM voltage - 45 to 48 volts is acceptable. Anything lower than 45 and the FICM needs to be replaced. If FICM output voltage is 0, check FICM vehicle power relay (#304, labeled IDM relay in owners manual). Replace FICM relay when replacing FICM regardless of condition. Note - engine may still run if FICM voltage is lower than 45v, but this signifies a failure is highly likely in the near future.

Verify FICM sync - FICM sync should read a "1" bit (1 for yes, 0 for no) while engine is being cranked or running. A "yes" or "1" value for FICM sync indicates that the FICM is receiving CPS/CKP signal from the PCM. If FICM sync returns a "0" or "no" value, CPS/CKP signal is not being transmitted to the FICM. Verify sensor conditions, connectors, and all wiring to the PCM and FICM.

Verify CPS, CKP sensor - If a camshaft or crankshaft position sensor loses signal a DTC will be set. A P2614 and P2617 DTC may be set simultaneously during a long crank condition when there is in fact no problem with either signal. CKP sensor failures are rare. CPS failures are more common. The odds that both sensors will fail together is slim-to-none.

Verify fuel pressure - A port on the fuel filter housing is used to measure fuel pressure. A schrader valve fitting is required to adapt most common fuel pressure gages to the port. 45 psi minimum should be observed KOEO, while cranking, and KOER. Any reading below 45 psi indicates a plugged fuel filter, fuel system leak, or faulty lift pump.

Verify fuel quality, drain fuel-water separator - Drain the frame mounted fuel-water separator and check for excessive water in the fuel. Cycle key to the "run" position several times, then drain and check again. If water continues to fill the separator, the fuel tank may need to be drained. Running an engine with excessive water in the fuel may damage injectors.

Perform an injector buzz test - An injector "buzz" or "click" test is performed to identify a bad injector or injectors by means of an audible test. When an injector buzz test is initiated the engine will sequentially activate each individual injector solenoid, producing buzzing and clicking sounds as the solenoids are energized. All injectors should produce the same characteristic buzz/clicking sound; any injector that sounds different from the rest should be inspected and may require replacement. If no injectors buzz once the test is initiated, retest the FICM.

Perform a cylinder contribution test - A cylinder contribution or power balance test determines how each individual injector contributes to engine rpm following an injection event. A weak injector will not contribute as much as a strong injector and thus engine rpm will decrease after that injector is fired. The FICM automatically adjusts injector pulse width to account for variances between injection event strength. This function must be briefly turned off in order to perform this test. This is achieved by selecting an injector as if you were to turn it off manually via your scantool/diagnostic system. Select any injector, but do not disable it; this will give you roughly 1 minute to initiate the power balance test before the automatic pulse width adjustment function returns. A straight line is desirable in the results of the cylinder contribution test. If rpm drops significantly for one or more injectors, they should be replaced.

Hard start, stalling only when engine is cold - Suspect high pressure oil system leak. A leak in the high pressure oil system may allow oil to drain out of the system while the engine sits. Monitor ICP; if ICP is low but finally reaches a normal state after excessive cranking and/or following a series of stall events, the HPOP may be starving for oil until the reservoir is refilled. Perform aforementioned ICP, IPR monitoring tests while engine is running to verify that the system functions within spec once engine is able to warm up.

Engine only stalls/will not start when hot - Check FICM voltage with engine at operating temperature. Suspect high pressure oil leak at STC (snap-to-connect) fitting on high pressure oil pump; extremely common.

Powertrain control module (PCM) - There is not a suitable nor standardized test for a PCM unless it is completely blank. All other systems should be tested thoroughly before assuming that a PCM is suspect. PCM failures do happen, but are less common than the aforementioned possibilities. The failure rate is much higher on engines with aftermarket tuners/programmers. Thoroughly inspect wiring harness for chaffing before suspecting PCM. If a no start condition occurs immediately following aftermarket tunes being uploaded, the PCM is likely the problem.

Low Power, Performance, & Driveability Concerns

Over-boost condition - A clogged EGR valve where the valve becomes stuck in the closed position can cause an over-boost condition (excessive MAP). Sticking vanes/unison ring in the turbine housing of the turbocharger can also cause an over-boost condition. If MAP is high under light load conditions, VGT vanes are sticking/stuck.

Low power condition, excessive turbocharger lag and/or low turbocharger boost - A number of PIDs need to be monitored in order to identify low power and poor turbocharger performance conditions. Causes include a stuck unison ring in the turbine housing, faulty VGT solenoid, exhaust leak, intake leak (pressure side of turbo), faulty EBP sensor, or faulty MAP sensor. The MAP and EBP sensors can be checked with KOEO. They should both read ~ 14.7 psi at sea level.

Excessive or insufficient EGR flow, low power condition - An EGR valve stuck in the open position can cause a low performance condition. If an EGR DTC is present, the first step is to remove, clean, and reinstall the EGR valve with new gaskets. You can also test the EGR position range by manually commanding it open and close; you will hear the idle sound change when the valve position changes.

Engine jerking, cutting in and out, low power - Fuel pressure, oil pressure, and injector condition can cause such symptoms. Start by testing fuel pressure under load, followed by verifying ICP/IPR function. If these systems are operating within spec, run an injector buzz test.

Clogged oil cooler - The pressure differential between EOT and ECT should not exceed 10 degrees F once the engine has reached operating temperature. If the temperature difference exceeds this by a wide margin, the oil cooler is likely clogged. Coolant blowing out of the degas bottle is a sign that the oil cooler has failed.

Identifying a failed EGR cooler - Loss of engine coolant is the most prominent sign that an EGR cooler has failed. In extreme cases, steam will be emitted out of the tailpipe. A simple way to check the EGR cooler condition is to pull the EGR valve. If there is any white residue or white "crystals" stuck to the EGR valve, the cooler is leaking and needs to be replaced.

6.0L Power Stroke Diagnostic Parameter Specs & Ranges

| Parameter | KOEO Spec/Range | Engine Cranking Spec/Range | KOER Spec/Range |

| ICP sensor pressure | 0 psi | 500 psi min to start engine | 650 - 800 psi @ idle |

| ICP sensor voltage | --- | 0.80 volts min | --- |

| IPR valve duty cycle | ~14 - 15% | ~ 84% until ICP rises | 30% max @ idle (22 - 28% normal) |

| Engine RPM | --- | ~ 200 rpm | 650 - 750 rpm @ idle |

| FICM main power | 45 - 48 volts | 45 - 48 volts | 45 - 48 volts |

| FICM logic power | 11 - 12 volts | 11 - 12 volts | nominal 12 volts |

| FICM vehicle power | 11 - 12 volts | 11 - 12 volts | nominal 12 volts |

| Manifold absolute pressure (MAP) | ~ 14.7 (sea level) - 11.3 (7,000 ft) psi | --- | MAP = MGP + BARO |

| Manifold gauge pressure (MGP) | 0 psi | --- | 0 - 28 psi (22 psi min @ full load, 3,300 rpm) |

| Barometric pressure | ~ 14.7 (sea level) - 11.3 (7,000 ft) psi | --- | --- |

| Glow plug duty cycle (preheat + post cycle) | 0 - 120 seconds | --- | --- |

| Glow plug resistance | 0.5 - 2.0 Ω (KEY OFF) | --- | --- |

| Glow plug current draw (preheat cycle) | 10 - 12 amps per glow plug (40 - 48 amps per bank) |

--- | --- |

| Fuel pressure | > 45 psi all conditions including full load (45 - 55 psi typical) | ||

| EGR valve duty cycle closed position | 0% | --- | --- |

| EGR valve voltage closed position | 0.6 - 1.2 volts | --- | --- |

| EGR valve duty cycle open position | 90 - 100% | --- | --- |

| EGR valve voltage open position | 4.0 - 4.52 volts | --- | --- |

Common Ford Part Numbers

See 6.0L Power Stroke Maintenance Schedule, Fluid Capacities Service Information for part numbers related to engine maintenance procedures.

| Part Description | Part Number(s) | Notes | |

| EGR valve gasket set | Ford 3C3Z-9P455-AB | Includes both o-rings and gasket, required when removing EGR to clean | |

| ICP sensor | 2003 - early 2004 | Ford 3C3Z-9F838-EA | Recommend replacing ICP sensor pigtail also |

| Late 2004 - 2007 | Ford 4C3Z-9F838-A | ||

| ICP sensor pigtail | Ford 5C3Z-12224-A | Splice in new pigtail when replacing ICP sensor | |

| IPR valve | 2003 - early 2004 | Ford 3C3Z-9C968-AA | Located behind/below turbocharger |

| Late 2004 - 2007 | Ford 5C3Z-9C968-CA | ||

| EBP sensor | 2003 - 2004 | Motorcraft DPFE-3 | 2003 and early 2004 engines do not use EBP sensor readings thus this item is rarely replaced on these MY engines. Clean EBP sensor tube anytime sensor is removed and/or replaced. |

| 2005 - 2007 | Ford 5C3Z-9J460-B | ||

| Camshaft position sensor (CPS) | Ford 8C3Z-12K073-A | Located driver side of engine block | |

| Crankshaft position sensor (CKP) | Ford 3C3Z-6C315-AA | Located passenger side of engine block behind AC compressor | |

| Manifold absolute pressure sensor (MAP) | Motorcraft CX-1961 | Replace MAP sensor hose if cracked, damaged, covered in oil, etc. Part number is Ford 4C2Z-9L474-AA | |

| 2003 - early 2004 glow plug | Motorcraft ZD-12 | 2003 - early 2004 glow plugs CANNOT be used in late 2004+ engines; they will contact the piston and cause severe damage. 9/29/2003 is the ENGINE build date cutoff. Early 2004 MY trucks received 2003 MY engines. | |

| Late 2004 - 2007 glow plug | Motorcraft ZD-13 | ||

| 2003 - early 2004 glow plug harness | Driver side | Ford 3C3Z-12A690-AA | Solid "busbar" style harness. Fits engines built 8/18/2003 and earlier. |

| Passenger side | Ford 3C3Z-12A690-BA | ||

| Late 2004 - 2007 glow plug harness | Driver side | Ford 5C3Z-12A690-A | Flexible "daisy chained" style harness. Fits engines build 1/15/2004 and later. |

| Passenger side | Ford 4C2Z-12A690-AB | ||

| Fuel pressure regulator upgrade | Ford 6E7Z-9C165-B International 1854267C94 |

Blue spring, factory Ford upgrade, increases fuel pressure. Inexpensive solution to fuel pressure that is at the low end of Ford's spec. | |

| Fuel pressure schrader valve | Motorcraft - CM3461 |

Replaces fuel test port plug with schrader valve | |

| Turbocharger reinstall kit | Ford 3C3Z-9T514-AG | All model years, turbocharger reinstall hardware/seals | |

| Turbocharger rebuild kit | Garrett 740659-0010 | Complete rebuild kit, all model years | |

| VGT solenoid | Garrett 792593-0001 | Controls VGT vane position | |